Our state-of-the-art electric arc furnace is in demand

Date:2022/7/8 Source: CISDI

CISDI’s constant progress in green melting research and development has paid off - the company’s green electric arc furnace - CISDI AutoARC and CISDI SuperARC have been industrialised and are now sought-after products in the Chinese market.

VALIN Hengyang’s CISDI AutoARC

An order for two CISDI AutoARC EAF has been placed by VALIN Hengyang in China’s Hunan Province. The furnaces will feature these 2nd-generation advanced technologies and benefits:

ü cascade distribution and continuous charging of raw materials

ü AC power

ü multiple melting systems for different material compositions: 60 percent scrap plus 40 percent hot metal can be charged into the EAF, reserving an all-scrap charge for use when required

ü continuous transportation of scrap into the horizontal section via a caterpillar conveyor enables a fast charging at scrap’s preheating section and its batching bays - an innovative method for enhancing productivity

ü scrap is preheated and continuously charged on the cascading channel, in step with continuous hot metal-pouring from a dedicated, tiltable hot metal ladle car.

As a result, the furnace’s power-on time is 15 per cent shorter and production capacity is enhanced by more than 25 per cent over conventional furnaces operating in the same working conditions.

CISDI AutoARC EAF at VALIN is designed to achieve an average tap-to-tap cycle time of 32 minutes per heat and a meting power consumption of 190kWh per tonne of liquid steel.

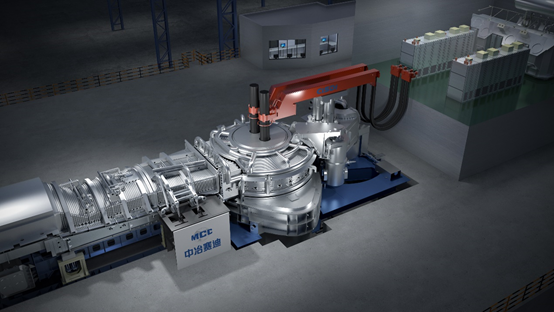

Yunnan Xianfu Steel’s CISDI SuperARC

A 70-tonne CISDI SuperARC EAF and a twin ladle furnace are currently being designed and manufactured at CISDI for Xianfu Steel in China’s Yunnan Province.

The CISDI SuperARC EAF features the combined advantages of CISDI’s unique 3rd-generation products:

ü an innovative IGBT-based flexible DC power

ü cascaded distribution and continuous charging of raw materials

ü an air-cooled bottom anode with feeler pins

ü scrap preheating

ü dioxin control expertise

ü a fume waste heat recovery system

ü intelligent production units

ü an advanced automation control system.

This expertise and advanced equipment meets melting energy requirements and addresses short-circuit over-current impacts faced by the DC EAF.

The Xianfu SuperARC furnace feeds with full scrap, reserving capacity for melting with 70 per cent scrap and 30 per cent hot metal when required.

Scrap is charged by a caterpillar conveyor and a cascade distribution system onto the horizontal continuous charging section, in synchronisation with a dedicated hot metal ladle car with a tilting function, which continuously pours hot metal into the furnace.

IGBT-based flexible DC power features a modular design. It allows a swift rejection in the event of a module’s failure. Other modules continue to work without cutting off power in the system.

The CISDI SuperARC EAF will achieve an average tap-to-tap cycle time of under 30 minutes per heat, and a melting power consumption of less than 300kWh per tonne of liquid steel, with full scrap charged.

A model of CISDI’s SuperARC EAF

Another model of the innovative, greener melting equipment